With the many extrusion systems across all plants, RKW has some need for skilled personnel to operate these complex installations. This is exactly what you learn through the process mechanic for plastics and rubber technology apprenticeship program.

The giant white balloon shoots upwards incessantly, the structure vibrating like a huge soap bubble in the wind. The extruders hum as they melt the hard granulate into liquid-hot form and shoot it out. At the same time, cool air hissing from below blows into the liquid plastic stream - the bubble grows. Far above, however, it is squeezed off and moved downward over conveyor rollers, and the balloon then becomes what it is all about here, foil.

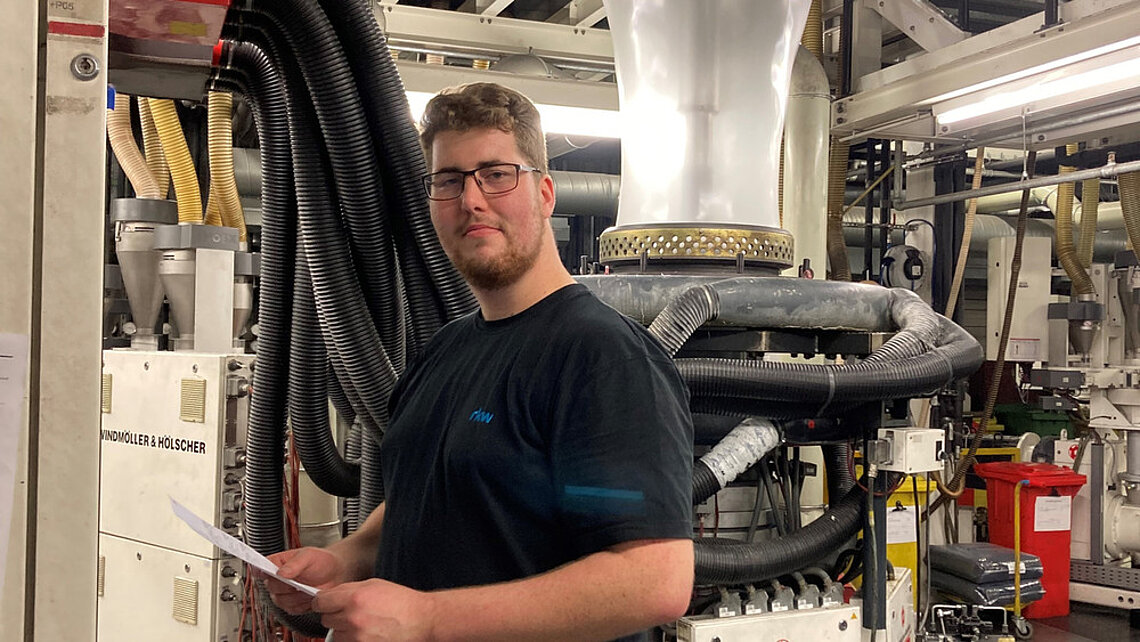

The plant runs practically around the clock, 365 days a year. It is the responsibility of colleagues like Maik Verwey to ensure that everything runs smoothly and that the changeover for new orders is quick and safe.

Maik had recently successfully completed his training as a process mechanic for plastics and rubber technology at RKW in Nordhorn. But how did he come to the decision to do this training and how did he fare during his training? Maik is 23 years old and came to RKW through his friends. This shows that word of a successful apprenticeship gets around and can bring in new and motivated apprentices in this way. At the beginning, he had doubts about whether it was the right thing for him, because the shift work also got to him. But as soon as he had more responsibility and was allowed to operate the machines himself, that changed. When we asked him whether RKW had prepared him well for his final thesis and the job afterwards, he answered with a short but clear "Yes". Of course, we are very pleased about this, because hardly anything is more valuable than the satisfaction and success of our trainees.

What exactly does a process mechanic for plastics and rubber technology do and what are their tasks?

Process mechanics mainly work with machines. Their job is then to operate, monitor and, if necessary, maintain these machines. Even the smallest error in the setting of the machine can have immense effects on the end product. For someone who has an aversion to math, physics and chemistry, the job is probably not for you. Manual dexterity and technical understanding are also welcome in this profession. You can compare the job to a chef in some places. There are recipes, ingredients, the right tools, a lot of heat, and in the end, what has been planned beforehand comes out. You use chemical and physical processes to shape a polymer material into a product that satisfies our customers.

What are the tasks of process mechanic for plastics and rubber technology at RKW in Nordhorn?

- They plan the production of plastic films

- set up machines and equipment

- operate the equipment and regulate the production process

- check the quality of the products

- apply technical documentation

- plan and control work and motion sequences on the extruder systems

- assist with maintenance and servicing tasks

Commenting on the importance of trainees in the profession at RKW Nordhorn, Fritz Sloot, head of training at RKW in Nordhorn, said:

"I would rate this as high. Trained personnel are the only way to ensure that our plants and their products can be manufactured in terms of quality requirements."

Apprentices are an important part of all our sites and anyone considering an apprenticeship as a process mechanic is welcome to apply.